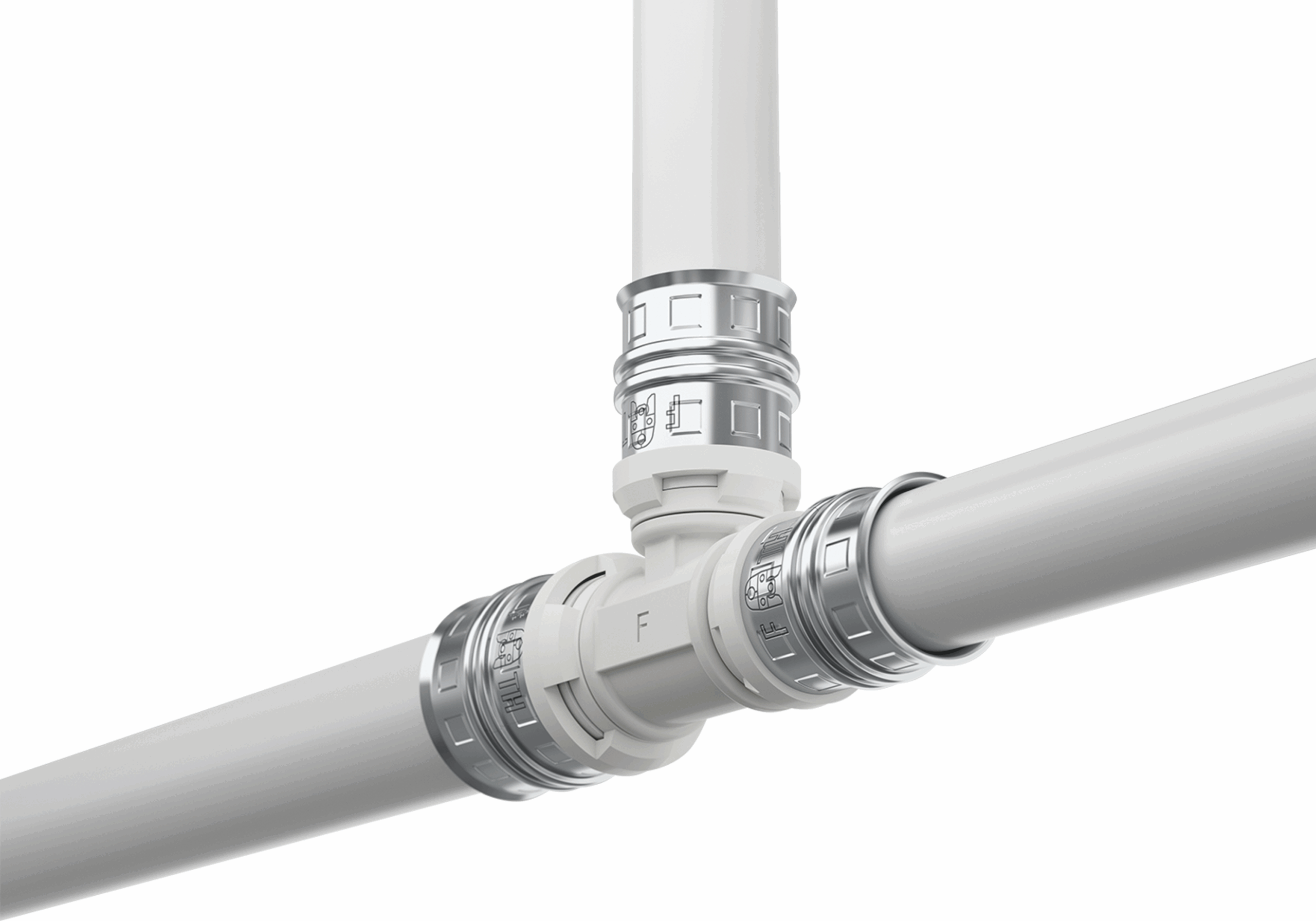

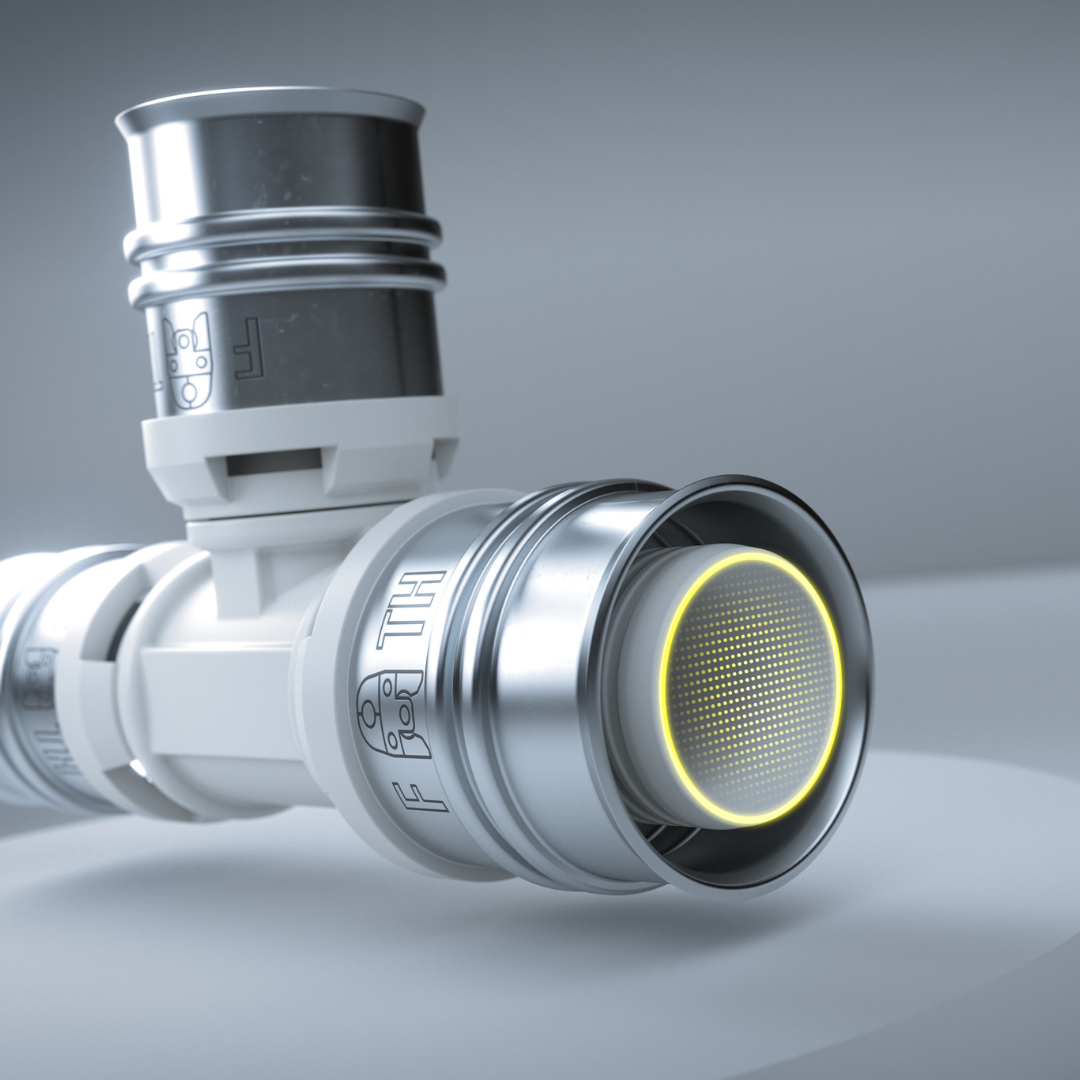

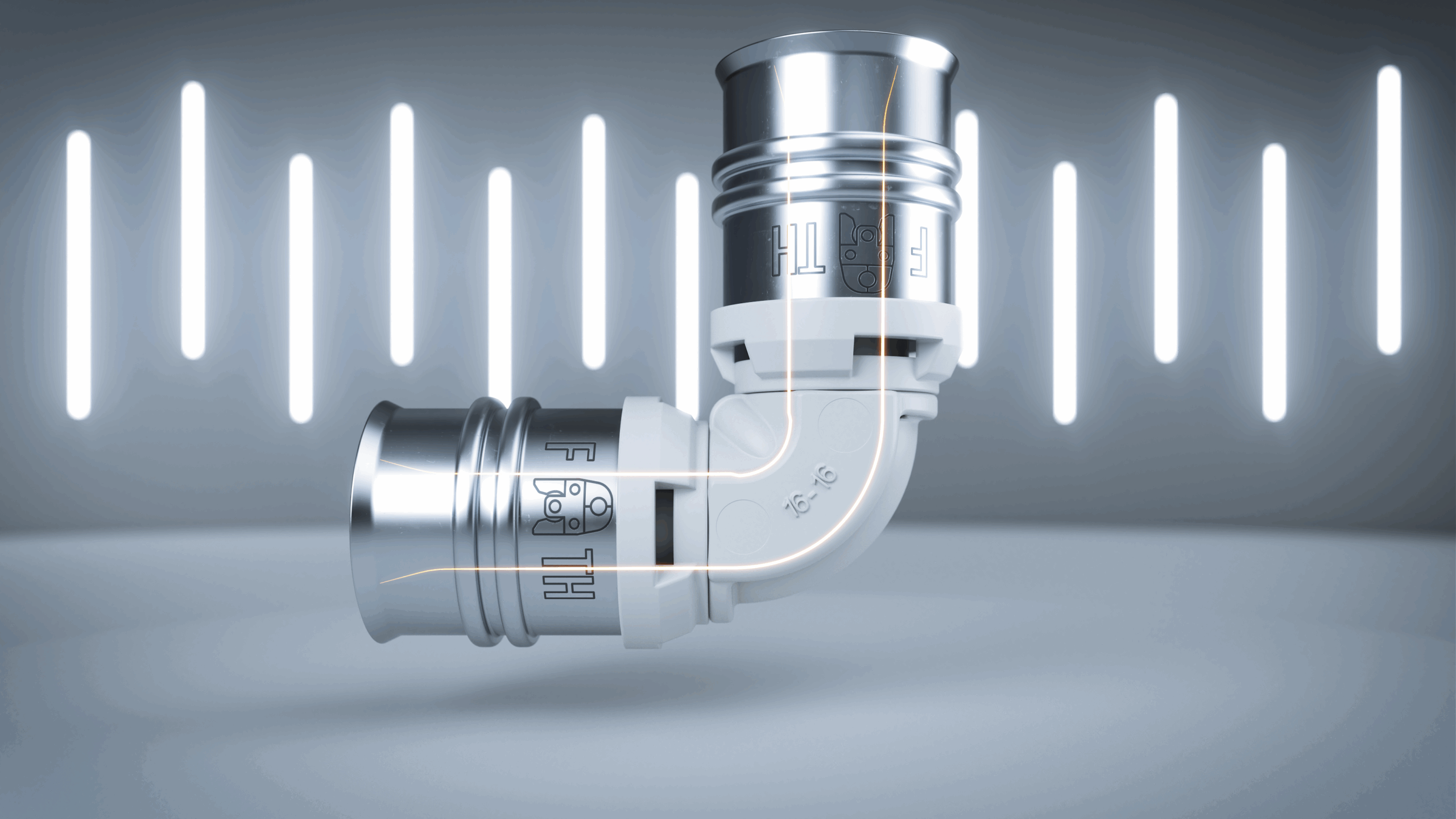

alpex – the next step.

The success story of the alpex system for heating and drinking water installations has continued for more than 25 years. It has been marked by ongoing development aimed to meet the constantly changing requirements regarding material quality and installation technology. The main focus remains on safety and durability, easy installation, and utmost hygiene.